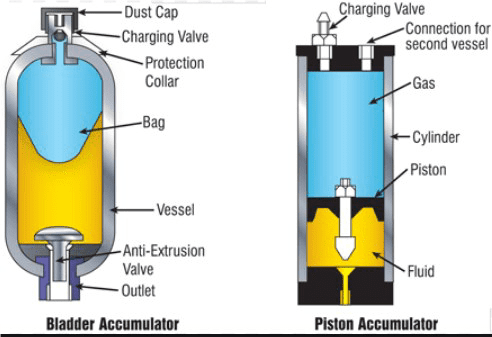

A hydraulic accumulator is a pressure storage reservoir in which a non-compressible fluid is held under pressure by an external source. The external source can be a spring, a raised weight, or a compressed gas. The two most common types of accumulators are bladder and piston types.

Before disassembling the accumulator, completely decompress the internal pressure in hydraulic line to atmospheric pressure, release gas from the accumulator and make it equal to atmospheric pressure. If excessive internal pressure is remaining in the line, the gas will blow out during disassembly, which may result in accident.

Accumulators should always be charged with dry nitrogen, never oxygen or compressed air. While technically not an “inert” gas, dry nitrogen does not react readily with other chemicals. Oxygen and compressed air aid combustion. Most accumulators have a safe-ty sticker on the shell warning that only nitrogen should be used for pre-charging.

An accumulator should be properly clamped to a mounting fixture. When assembling the accumulator after bladder replacement, the retainer ring is fitted around the outside of the poppet valve, and both are inserted into the accumulator shell. If the accumulator shell is not properly clamped, then failure of the retainer ring can cause the poppet valve to disconnect from the accumulator. This can result in the shell taking off like a rocket.

Suggestions on how to prevent accumulator valve accidents:

- Develop of safety standards for evaluating safety when purchasing new equipment and evaluation of existing equipment for proper safety measures and standards.

- Evaluate safety standards and determine what component(s) and information is available to safely service and/or repair a gas-charged, hydraulic accumulator.

- Provide proper service and repair equipment available to maintenance personnel.

- Provide training to technical personnel that will be working on hydraulic accumulator equipment and ensure ongoing training, education and awareness is provided to those personnel.

- Discuss proper use of service and repair equipment in your safety meetings and during safety shop talks.

- Discuss medical complications associated with oil and air injection injuries.

- Development of a “JSA” job safety analysis for correct techniques for servicing and/or repairing a gas-charged, hydraulic accumulator.

- Encourage personnel to report non-injury accidents (NIA’s) associated with servicing and/ or repairing gas-charged, hydraulic accumulators, for the purpose of accident prevention.

- A gas-charged accumulator provides a unique safety hazard.

- Recommend the development of in-house “certification” program for technicians who work with gas-charged accumulators. Only “certified” team-members should be permitted to service and/or repair a gas-charged, hydraulic accumulator.